Imagine you are launching a new silicone product line that offers flawless coatings and durable finishes, dazzling your core audience. A little-known secret lies behind this product line, a secret unknown to your industry rivals, i.e., silicone surface activation. This process is a game-changer that can transform inert silicone into a high-performance material ready to bond with all sorts of inks & adhesives. Rest assured, silicone’s core (physical) properties remain unchanged.

If you want your silicone-based products to not just meet but exceed market expectations, learn what silicone rubber surface activation means. That’s how you can make your brand stand out in competitive retail channels confidently. Let’s explore how this breakthrough takes your silicone products to the next level. We shall go over the process by referring to the original patent.

What is Silicone Surface Activation Treatment?

Silicone surface activation treatment is a very recent breakthrough in this industry. It’s rooted in the long history of silicone use and innovation. Silicone is a synthetic material discovered in the late 1700s and developed over the next two centuries. Jöns Jacob Berzelius, the person credited with discovering selenium, first isolated silicon in the 1820s. It soon became the “poor man's alloying agent” because of its uncanny resilience and unique, industry-specific properties.

But silicone’s inherent chemical inertness made it hard to bond and apply surface treatments in industrial applications. So, scientists started looking for unique ways to alter the silicone rubber surface without compromising its beneficial bulk properties. Originally, treatments like plasma & chemical processing were used; today, we have BPA-free silicone beads and other items.

7 Chemical Principles of Silicone Rubber Surface Activation

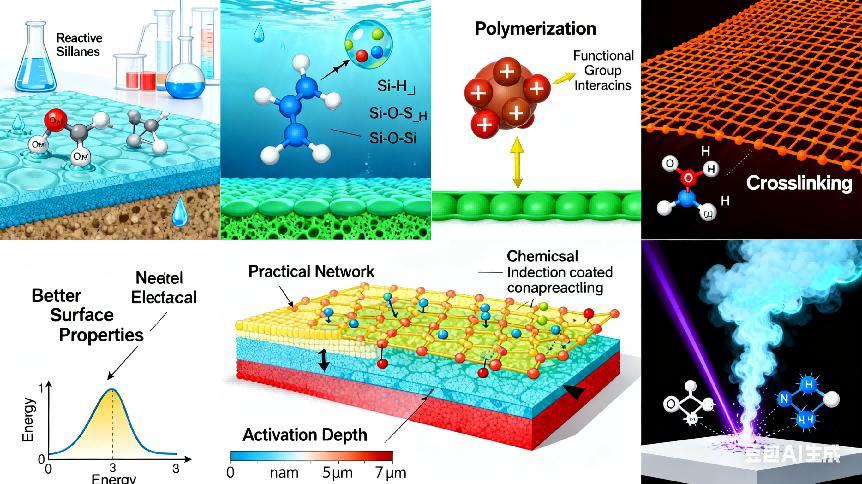

Here’s one thing you need to know about this process. The concept of surface activation refers to introducing reactive groups to silicone or modifying its surface topology to make sure that your raw silicone gives better adhesion and coating compatibility. We’ll discuss this process later, but first, you need to understand the seven major chemical principles governing it:

1.Reactive Silanes: This process uses reactive silanes as chemical agents. They have at least one hydrolysable group (methoxy/ethoxy) attached to silicone. Moreover, they contain functional groups that lead to covalent bonding with external adhesives.

2.Silanol Formation:Silanes undergo hydrolysis when you expose them to moisture, so you get silanol groups (Si-OH). It condenses with silanol groups on the silicone surface to form strong Si-O-Si covalent bonds.

3.Functional Group Interactions:Then, introducing nucleophilic (electron-donating) or electrophilic (electron-accepting) functional groups on the silane molecules boosts the next few chemical reactions that make your silicone better at adhesion.

4.Polymerization & Crosslinking:Different thermal/environmental conditions promote silicone molecule polymerization on the silicone surface. You see a crosslinked network forming there that is bonded chemically to the silicone substrate.

5.Better Surface Properties:Now, this chemically altered network raises the energy of the silicone surface. It provides reactive sites for further bonding with your hydrophilic coatings and even ink/adhesives.

6.Activation Depth: The depth of silicone varies from nanometers to microns (one micron is one-millionth of a meter). It depends on chemical diffusion and reaction extent.

7.Plasma & UV Methods: As we mentioned earlier, plasma & UV activation methods will complement this process by breaking surface molecular bonds and generating reactive radicals. They add polar groups like hydroxyls or amines to make silicone rubber more chemically reactive.

Rubber Surface Activation Process: 5 Steps

If you’ve understood these principles, we can explain the actual process to you here. The rubber silicone surface activation process gives you a homogeneous and durable interface that can meet the demanding requirements of different industrial & medical applications. We’ll use the Google patent for this technology to write down these steps.

1.Preparing the Surface

This process begins as you clean the surface of silicone rubber to make sure there’s no dirt, oil, or other contaminants on it. You’ll rinse the surface. Apply sonication. You may also wipe it with solvents like alcohols or alkanes. Proper cleaning helps you ensure that your reactive agents can uniformly access the silicone surface for the next four steps.

2.Swelling the Silicone Surface

Next, you’ll use suitable solvents like pentane/hexane to swell the silicone. You can use organic solvents for this purpose as well. Swelling makes the silicone matrix more receptive by opening its structure. So, reactive chemicals can penetrate deeper into the surface layer. The time it takes for the rubber surface to swell should be controlled carefully. You shall decide how much depth you need, and then set the timer accordingly.

3.Reactive Silane Application

Now, you’ll get a treatment solution. It’ll contain reactive silanes, i.e., chemicals with functional and hydrolyzable groups. You’ll apply this treatment to the rubber surface. The silanes diffuse into the swollen silicone surface, where they undergo hydrolysis. As we’ve explained before, this stage converts alkoxy groups into silanol groups (Si-OH). Now, these silanol groups will bond chemically with the surface of silicone (or with each other). You get a covalent network.

4.Hydrolysis and Cross-Linking

Once the silane molecules are bonded to the surface, they undergo further hydrolysis. They can build a cross-linked silane network. This network introduces reactive groups that later interact with your coatings, inks, etc. Now, the silicone rubber has a more chemically active & compatible surface.

5.Thermal/Environmental Curing

The final step deals with heat treatment or curing. You will do it under controlled environmental conditions. This promotes covalent bonding, along with the oligomerization & polymerization of silane molecules. You’ll get a stable, functionalized surface that improves adhesion and gives you a better surface energy.

Comparing the Effects of Silicone Activation: Before vs. After

Silicone surface activation transforms the chemical attributes of silicone rubber. This process alters its bonding capabilities and functional performance. Silicone rubber is inert before the process; it has low surface energy, not suitable for ink/coating adhesion. If you use this silicone type, you’ll face problems like peeling, uneven coatings, reduced aesthetic appeal, etc.

However, activating this rubber silicone surface introduces reactive groups that increase surface energy and adhesion properties. This change makes sure that your silicone is ready for coatings; it has adhesives bonded tightly & uniformly, enhancing its performance and reliability.

Before | After | |

Chemical Reactivity | Chemically inert (doesn’t have reactive surface groups) | Surface enriched with reactive groups (silanols) |

Surface Energy | Low surface energy (repels adhesives & coatings) | High surface energy (promotes uniform adhesion) |

Adhesion Quality | Weak bonding (coatings may peel or flake) | Strong covalent bonding with coatings & adhesives |

Wettability | Poor wettability (liquids bead up unevenly) | Better wettability (smooth and even coating) |

Print & Coating Durability | Weak ink adhesion (prints fade or wear off quickly) | Durable (you get sharp prints and wear-resistant coatings) |

Surface Hydrophilicity | Hydrophobic (not compatible with hydrophilic materials) | Surface can be made hydrophilic purposefully |

Process Complexity | Minimal surface preparation required (quality is limited) | Precise treatment needed (but yields superior quality) |

Range of Applications | Limited due to bonding issues | Expanded use in medical and consumer goods markets |

Silicone Surface Activation vs. Surface Coating/Spraying

You must realize that silicone materials come in different shapes & forms. For instance, there is a major difference between solid silicone and liquid silicone materials. These differences show us that liquid silicone is a fluid with high transparency and food-grade safety. You should use these materials to manufacture baby products & medical items. The same way, activating the surface of silicone is very different from surface coating/spraying; these treatments are very different.

Surface activation modifies the silicone surface chemically. It gives a robust, nano-reactive layer that leads to better adhesion and durability. You get a better tactile feel without adding thickness or affecting the original properties of silicone. Surface coating applies an external layer onto the silicone.We have provided a brief comparison of these two treatment processes in this table as an overview:

Surface Coating/Spraying | Silicone Surface Activation Treatment | |

Process | Applies paint, solvent, or coatings onto silicone surface | Uses UV/plasma or chemical methods to modify silicone surface |

Impact on the Material | Adds a layer on top (may affect silicone’s flexibility & thickness) | Only surface molecular chains are changed (non change in the thickness) |

Durability | Limited (these coatings can peel, wear off, or degrade) | Excellent (chemically bonded and lasting surface changes) |

Environmental Concerns | Involves solvents and waste (liquid, solid, gas, etc.) | Very low (mainly trace ozone gas, no solvents/coatings) |

Surface Feel | Varies (it can feel different or tacky) | Soft (delicate and smooth hand feeling) |

Surface Stability | Coatings may discolor or degrade over time | Maintains color stability and surface integrity |

Adhesion Performance | Good (initially), but may deteriorate over time | Superior adhesion with no delamination |

Anti-Static & Cleanliness | Often requires additional treatments | Achieves anti-static, dust-repellent surface |

Application Suitability | Suitable for short-term or decorative uses | Ideal for high-performance applications like wearables and kitchenware |

KEAN Silicone Surface Activation Treatment

At KEAN, we turn the science of surface activation into tangible advantages for your products. Our expertise is not limited to a single method; we have mastered a diverse portfolio of activation processes, including advanced UVC and plasma technologies. This versatility is powered by a unique blend of deeply experienced craftsmen, highly mechanized production lines. Our skilled technicians bring years of hands-on knowledge to fine tune every parameter, while our advanced automated systems guarantee unwavering consistency and superior efficiency for every order.

We understand that there is no one-size-fits-all solution. That's why we don't just sell a standard process we provide a customized, comprehensive surface treatment strategy. Our technical team conducts an in-depth analysis of your specific product, its intended use, and performance requirements to recommend the most suitable and effective activation method. This consultative approach ensures your silicone components achieve optimal adhesion, durability, and functionality.

Furthermore, choosing KEAN means making a responsible choice for your business and the planet. Our modern UVC-led processes are designed to be highly eco-friendly, significantly reducing or eliminating the need for solvents and chemical waste. This green technology translates directly into a cost-effective solution for you, minimizing operational expenses and ensuring your products stand out for their quality, reliability, and environmental compliance.

Final Remarks

Partner with Kean Silicone for expertly crafted, high-quality silicone products tailored to your brand's needs. With over 15 years of industry expertise, we offer innovative solutions, easy sampling, and customized designs that ensure reliability, safety, and market appeal. Contact us today to elevate your silicone product line.