KEAN Silicone Product Customize Process

As we all know, silicone products are a rising star on the market. Maybe you want to start your own brand career with a revolutionary silicone idea, or you already have a mature silicone idea but don't know how to start it. At this time, work with a professional silicone product manufacturer will be a wise choice.

KEAN Silicone, a leading silicone product manufacturer in China, has been providing the best quality products to our global customers.

Our one-stop service covers every stage of customized silicone products: from idea to design, molding, printing, packaging, and shipping. We are proud to say that with 15 years of experience in exporting and customizing, a strong R&D team, and a precision mold-making workshop, we can help you turn a silicone idea into reality!

KEAN's Production Facility No. 1

KEAN's Production Facility No. 1

Why choose us

KEAN has more than 300 product patents, 20+ product design engineers, 20+ production lines, our own mold room, and new designs coming every months. We are equipped with an independent and experienced R&D team and 2D/3D printing technical support.

We provide one-stop solutions to meet your scalability requirements, including a wide range of customizable items such as product shape, function, color, packaging, logo, pattern, and so on. Even if you only have an idea draft, our designer will give the most professional advice based on more than 10 years of design experience and the current market demand, creating a unique silicone products with differentiation for your business.

Our Factory is certified by BSCI, SEDEX, 1SO9001, FCCA, FSC, Disney, Target, SGS, GMP, and others.

Products pass: FDA, CPSC, EN-71, LFGB, CPC, CE, EN1400, EN12586, EN14372, GB4806, F963, ROHS or others.

Steps Involved in the Design and Customization Process

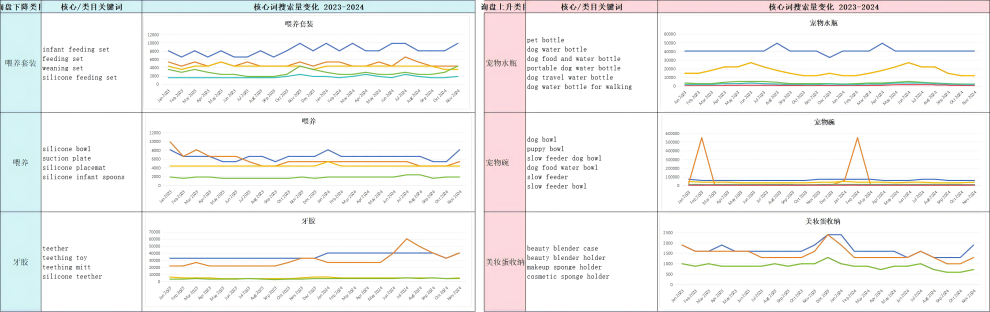

In fact, an experienced manufacturer can easily catch the opportunities to find the hidden gem by studying the recent products, and it is difficult to create the profitable products that buyers want without some market data to support them.

So choosing a silicone manufacturer with a global perspective and data resources in the industry as your partner will greatly reduce, the amount of time and effort spent on assessing the feasibility of a project in some ways.

This means that the manufacturers you need should be well-informed about consumer perceptions and preferences and up-to-date on the latest trends in the silicone industry.

Our products are wholesale on multiple platforms, including Amazon, Google, Alibaba, Made in China, etc. We have specialized data analytics tools that can provide you with data on the heat and search index of your existing products, as well as identify segments with high growth potential and areas for expansion in order to explore profitable markets in the silicone products industry, especially those with innovation and potential. Potential for innovation.

MOQ

The following data is based on most products of similar purposes as a reference. For the specific products of the MOQ, please consult info@keansilicone.com.

Teether: 500~1000

Mother and baby feeding: 100~500

Travel bottle: 100 for some teethers, 1000~3000 for most products of them.

Food storage: 1000

Other household: 1000

Water bottle: 1000~3000

Pet product: 100~1000

Silicone straw: 1000

Customization Needs And Creative Concepts Proposed

We communicate with our customers first to understand their specific needs or what they're probably looking for in initial inquiries.

Then, we provide them with the most appropriate customization plan, which includes the cost of customization, the direction of customization, material, structure, shape, sizes, color, logo, pattern, package, label, and any specific features or function specifications.

KEAN's team of professional designers is ready to evaluate the feasibility of your product design concepts. They are available to address any questions or concerns you may have and will work closely with you to finalize the preliminary design options and sketches.

Prototyping and Product Production Stage

Product Design:

All that is required is a CAD file containing the proper specifications for your molded silicone product project and then we will handle it as soon as possible. If you don't have a CAD file, that's OK, and we can also create a CAD based on the specifics of the manuscript, reference images, samples, etc.

Even if you only have an idea, our team of designers, which is highly sensitive to the market, will help our clients turn their abstract and complex ideas into reality step by step. And provide you with quality, design, and performance of reasonable and appropriate design solutions.

Materials:

We guarantee that each product is made of food-grade silicone, of course. However, in order to meet the diversified needs of our customers, we have also designed many other products made of other materials combined with silicone, including, but not limited to, wood, food-grade PP plastic, stainless steel, and so on.

3D Printing:

Once the product drawings and design are confirmed, our designer will use 3D modeling and 3D printing to check the details of the product, verify the feasibility of the design concept, and optimize the shape, structure, and function of the product to meet specific needs in our in-house design workshop.

|

|

| 3D Printing | The Molding Of Solid - State Silicone |

Mold Making:

Then, to ensure that our silicone products are produced in the best way our client wants, we use CNC machine engraving to create key components such as mold cores and cavities. Depending on the product's appearance and structural requirements, spark machines, lathes, milling machines, and other equipment are used to perform the fine polishing of the molds.

After fine polishing, such as hand lathe polishing molds, each mold component will be assembled by hand. Finally, we conduct sample mold testing for on-machine production and make trial molds to ensure the accuracy of the molds and the initial quality of the product.

Testing:

Our designers will give the drawings to the factory for sampling after determining that there is no problem with the appearance and structure of the product. And then, we will produce small batches of your customized goods that will be used to send to the authoritative institutions for testing and internal experiments in our lab and provide customers with test reports.

Such as BPA-Free certification, and FDA certification. Different products require different tests and certifications, such as silicone teething toys; we will conduct the throat test, pull test, impact test, etc.

|

|

|

| Tensile Strength Testing | Two - Dimensional Measurement | Simulation Coating Testing |

Mass production:

When our customers are satisfied with the molded silicone product samples, after a secondary vulcanization process to improve the strength, durability, and cleanliness of the silicone product and a shop floor UV dust protection treatment, we will mass produce their customized products in our factory production workshop, which has 20+ producing lines according to the sample communication result.

Coloring:

Silicone material has good coloring, light stability, and heat resistance, which means that there is almost no limit to the choice of color. We promise that all our products use safe, non-toxic dyes that comply with industry standards.

Logo & Label:

We have many printing options for your reference: silk screen printing, pad printing, heat transfer printing, water transfer printing, UV printing-digital printing, laser engraving printing, surface activation treatment (UV modification), and so on. If you are not sure about the specific process, you can also tell our salesman what kind of effect you want.

Quality Inspection and Packaging:

From the time the product is demolded until the finished product is put into storage, there are six quality inspection processes totally that perform a variety of tests, including pressure tests, heat tests, and safety compliance checks, to ensure that the final product is of the highest quality.

Also, throughout the production process, we conduct numerous random inspections on both semi-finished and finished products to ensure that each item you receive meets the highest standards of perfection.

Our salesman will share your product packaging ideas with our professional packaging designers for design and sampling, including cartons, gift boxes, color boxes, bags, cardboard, blisters, and other requirements.

Cooperation

1. Regular communication

At KEAN, we are committed to a customer-first approach, maintaining open and regular communication with our clients throughout the entire customization process. This includes providing updates on the progress of the design and production stages and seeking their input and approval for key processes.

Our goal is always to ensure that the final product not only brings our client's ideas to reality but also exceeds their expectations.

2. Build a network of partners

Collaboration is at the heart of our process at our custom silicone product manufacturing facility, and we firmly believe that building strong partnerships with our customers is the best way to find ways to produce the best silicone product together at a higher level.

3. Multi-Channel Marketing Strategy

Suppose you are pursuing the uniqueness of your products and wish to maintain this uniqueness on a specific shopping platform or globally. In that case, the exclusive distribution service we offer will be ideal for you.

By promising not to sell the same product to other customers, we protect your product's unique position in the marketplace and provide additional protection for your brand by contractually securing the legal validity of the underwriting service.