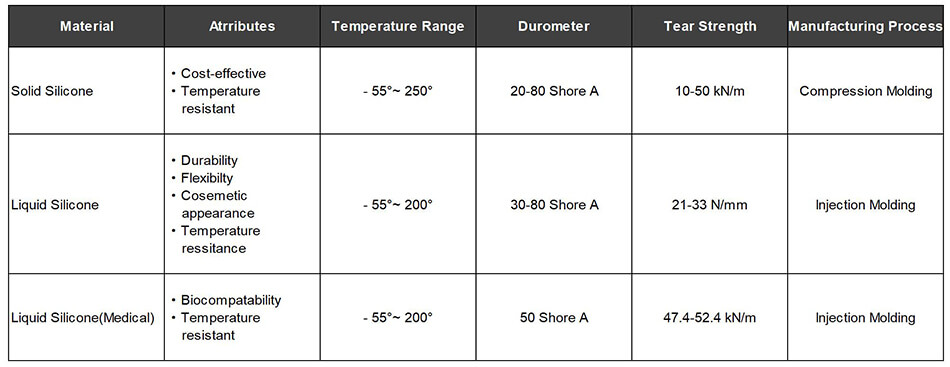

In the field of organic silicon, physical silicon rubber materials can be divided into solid and liquid materials, and both materials are currently widely used in various major industries, such as daily necessities, medical supplies, and sealing silicon Rubber products, mechanical components, and sealing silicon Rubber products, electronic sealing accessories, etc.

There are many similarities between their application fields and material properties, and their production processes are different. In the field of products, their roles and functions are basically the same. What are the differences between materials and products?

The main difference between liquid silica gel and solid silica gel is: one is liquid and the other is solid; Liquid silicone are an highly transparent and food-grade safe material, it does not need to add auxiliary material such as mold release agent during molding; Solid silica gel is in a solid state and has no fluidity, semi-transparent or milk white (Although a transparency enhancer can be added to improve clarity, the transparency is still not as good as liquid silicone rubber.)

What Is Solid Silicone Rubber (HTV)

Solid silicone rubber (HTV) is a saturated elastic polymer material in solid form, known for its stability, transparency, and environmental friendliness. It requires a vulcanizing agent during molding to shorten curing time and is typically processed by compression molding.

Mixed silicone rubber is made by blending reinforcing fillers and additives with polysiloxane as the base rubber in a mixer, forming a non-crosslinked compound.

Core Features:

Solid silicone offers a stable structure, strong physical properties, and excellent resistance to heat, cold, ozone, and weathering. It performs reliably from -60°C to +250°C and provides great insulation, crack and solvent resistance, and long-term durability.

Processing:

It is vulcanized at 140–165°C under pressure, making it ideal for compression-molded products such as thick-walled or large parts.

What Is Liquid Silicone Rubber (LSR)

Liquid silicone rubber (LSR) is a high-purity, two-component silicone material that remains liquid before curing. Compared to solid high-temperature vulcanized silicone (HTV), it offers better fluidity, faster curing, and higher safety and environmental performance. It can fully meet food-grade standards and withstand a wide temperature range from -40°C to 380°C.

LSR has excellent tear strength, elasticity, anti-yellowing, and thermal stability. It is transparent, non-toxic, and does not require additional vulcanizing agents or additives during molding. The two components (A and B) are precisely mixed and injected into molds using automated injection equipment, ensuring consistent quality and efficiency.

Main Types of Liquid Silicone Rubber:

Injection Molding LSR: The most widely used type, processed by injection molding machines for high precision, automation, and productivity. It is suitable for mass production of medical, baby care, and food-grade products.

Mold Silicone Rubber (RTV-2): Commonly used for crafts, molds, and prototyping applications.

Electronic Silicone Rubber (RTV-T): Designed for moisture-proof and insulating purposes in electronic components.

Sealant (RTV-1): Known as glass glue, used for sealing, waterproofing, and bonding in construction and electronics.

Different fields of use

(1) Liquid silicone is generally used in industries that require direct contact with food or the human body, such as baby products, some of kitchenware, and medical supplies; Compared to solid silicone rubber (HTV), liquid silicone rubber (LSR) has become a more premium choice for high-end brands due to its excellent fluidity, fast vulcanization, and safer, more environmentally friendly properties.

(2) Solid silica gel is generally used for daily necessities, industrial miscellaneous parts and auto parts such as sealing components, insulation; Solid silicone (HTV) molds are much affordable than liquid silicone ones,as they are made by compression molding rather than injection molding, and for most of daily necessities, solid silicone fully meets the necessary standards for both performance and safety.

(3) Safety of liquid silica gel and solid silica gel: Liquid silica gel is a highly transparent, high-safety food-grade material. No auxiliary materials such as vulcanizing agent are added during the molding process. The sealing material is formed by sealing.

Molding:

Liquid Silicone (LSR): The full name is injection molding liquid silicone rubber, and the vulcanization equipment is an injection molding machine. The injection molding machine process is very simple, the product precision is high, and the output is high (the A/B glue is mixed for a few seconds at a certain temperature).

The materials are mixed and added with color glue and catalyst to automatically inject into the mold cavity without manual operation. Product advantages The product has good fluidity, strong stretch and resilience, and the mold is combined injection molding, so the product has a plastic injection port and basically no surface parting lines.

Solid Silicone: The raw material for solid silica gel molding is a solid. After the silicone rubber product manufacturer is mixed by a mixer, it needs to add color glue and catalyst, and then cut it into an appropriate size and manually put it into the mold cavity to form and cure. The automatic processing method requires manual operation to take the mold and discharge the material. Because the material is solid, the fluidity and stretch resilience are slightly lower than that of the liquid. The product has no injection port, and the processed finished product will have upper and lower parting lines .

Making Process

(1). Solid silica gel is industrially made of water glass (sodium silicate) as a raw material, hydrolyzed in an acid medium to form a gel, and then made into silica gel through aging, washing, drying, etc., depending on the water content, translucent or white solid. The products on the market have irregular granular, spherical, and microspherical silica gels, which are usually used as catalysts for vulcanization in fluidized bed operations.

(2). When used as a catalyst carrier, the silica gel is usually immersed in a solution containing catalytically active components, so that the solution is absorbed into the pores of the silica gel, and the active components are distributed on the surface of the silica. Gelation through drying, activation, etc. The pore structure of silica gel has an important influence on the properties of the prepared supported catalyst, such as the pore volume and pore size distribution of silica gel. Generally, silica gel with an average pore diameter of less than 15 to 20 is called fine pore silica gel; and an average pore diameter of more than 40 to 50 angstroms is called coarse pore silica gel.

(3) The pore structure is not conducive to the diffusion of reactant molecules, but it can reduce the utilization rate of the inner surface of the catalyst, and the product molecules formed in the pores are not easy to escape from the pores, which is possible. Causes a profound side reaction. The pore structure of silica gel is related to the manufacturing method and conditions, such as gelation, aging, pH during washing, temperature, and time. Commercially available silicone daily necessities can be reamed through reaming. The usual method is to heat in an autoclave or add a salt-containing aqueous solution (such as sodium carbonate or sodium acetate), for example, at 320° C., 10 MPa hot-press treatment can change the specific silica gel. Surface and average pore size is 135㎡/g and 12.3㎡ to 26.9㎡/g.

Liquid silicone process introduction

Liquid silica gel is used in industry to dehydrate sodium water into silica sol through ion exchange. It is a translucent milky white liquid with high stability. The solid silica gel becomes a porous solid after drying. For example, in the preparation of (phosphorus-molybdenum-niobium-oxygen)/silica catalyst for preparing acrylonitrile by oxidative oxidation of propylene, a solution containing active components is mixed with silica sol, and microspheres are prepared by spraying catalyst.

Conclusion

Both liquid silicone rubber and solid silicone rubber have their own set of benefits and characteristics, if you have any problem of choosing the right material for your project, feel free to contact us: sale@keansilicone.com KEAN has rich experience in custom silicone product with both solid silicone rubber and liquid silicone rubber.