Choosing between Liquid Silicone Rubber (LSR) and High Consistency Rubber (HCR), especially as a brand owner developing products for babies, travel accessories, or household items, will help you determine the quality of your product, manufacturing costs, and market competitiveness. This decision affects everything from the initial investment in tooling to the total five-year costs of ownership.

Key Differences Between LSR and HCR

How Each Silicone Manufacturing Process Works

Liquid Silicone Rubber Production

LSR is usually a liquid system consisting of two components. Part A contains a silicone polymer base with silica reinforcement fillers. Part B is composed of a platinum catalyst and crosslinker. Automated metering systems combine these two components at milliseconds.

Under pressure of 1,000 to 2,000 psi, the mixed material is injected into heated molds at 170 to 200 °C. Then the low-viscosity liquid fills complex cavities, even those with sections as thin as 0.3mm. The platinum-catalyzed curing is completed in 30 to 120 seconds. Robotic systems automatically extract the finished parts.

Furthermore, closed-loop automation ensures molecular consistency. Each production unit has identical mechanical properties. This is critical for FDA compliance, and premium baby products that require absolute batch-to–batch reliability.

High Consistency Rubber Production

HCR is delivered in bulk in a solid putty-like form. Operators manually weigh, cut and place pre-forms in mold cavities. Hydraulic compression then presses close under 1,000 to 3,000 pounds per square inch. This forces material into the cavity while applying heat.

After the compression process, the solid material mass takes 3 to 10 minutes to cure. The next step is manual demolding, where operators remove parts, trimming flash from the parting line, and conduct individual inspection. To eliminate residual compounds, peroxide-cure formulations require treatment for 4 hours or more after curing.

HCR is accessible to smaller manufacturers, brand owners, and those testing market concepts before making a high-volume commitment.

Strategic Material Planning for Different Production Scales

Under 20,000 Units Annually

HCR offers optimal economics for limited quantities. When producing less than 20,000 units annually, the $30,000-$60,000 in tooling costs can’t be recovered through per-unit savings. On the other hand, the faster cycle times and lower labor costs of LSR fail to offset the $70,000+ extra tooling cost.

Some products are exempt from LSR requirements. Despite the volume being low, LSR may be justified for products such as baby bottle nipples that require 15 Shore A softness and collapsible containers with 0.5mm walls.

20,000 to 50,000 Unit Annually

This zone of transition requires detailed analysis. Your manufacturing region's labor costs have a significant impact on your economics. Low-wage countries keep HCR more competitive. High-wage countries favor LSR automation.

The cost is often not the most important factor when determining feasibility, but design complexity is. LSR selection is usually required when there are undercuts, thin sections and tight tolerances. Moreso, LSR is often chosen for medical devices or baby products that require a high level of quality, even at moderate volumes.

It is important to have realistic growth projections. Brands that expect rapid growth to 100,000 units or more over the next two years should start by using LSR. This avoids costly supplier changes and retooling in mid-growth.

Above 50,000 Units Annually

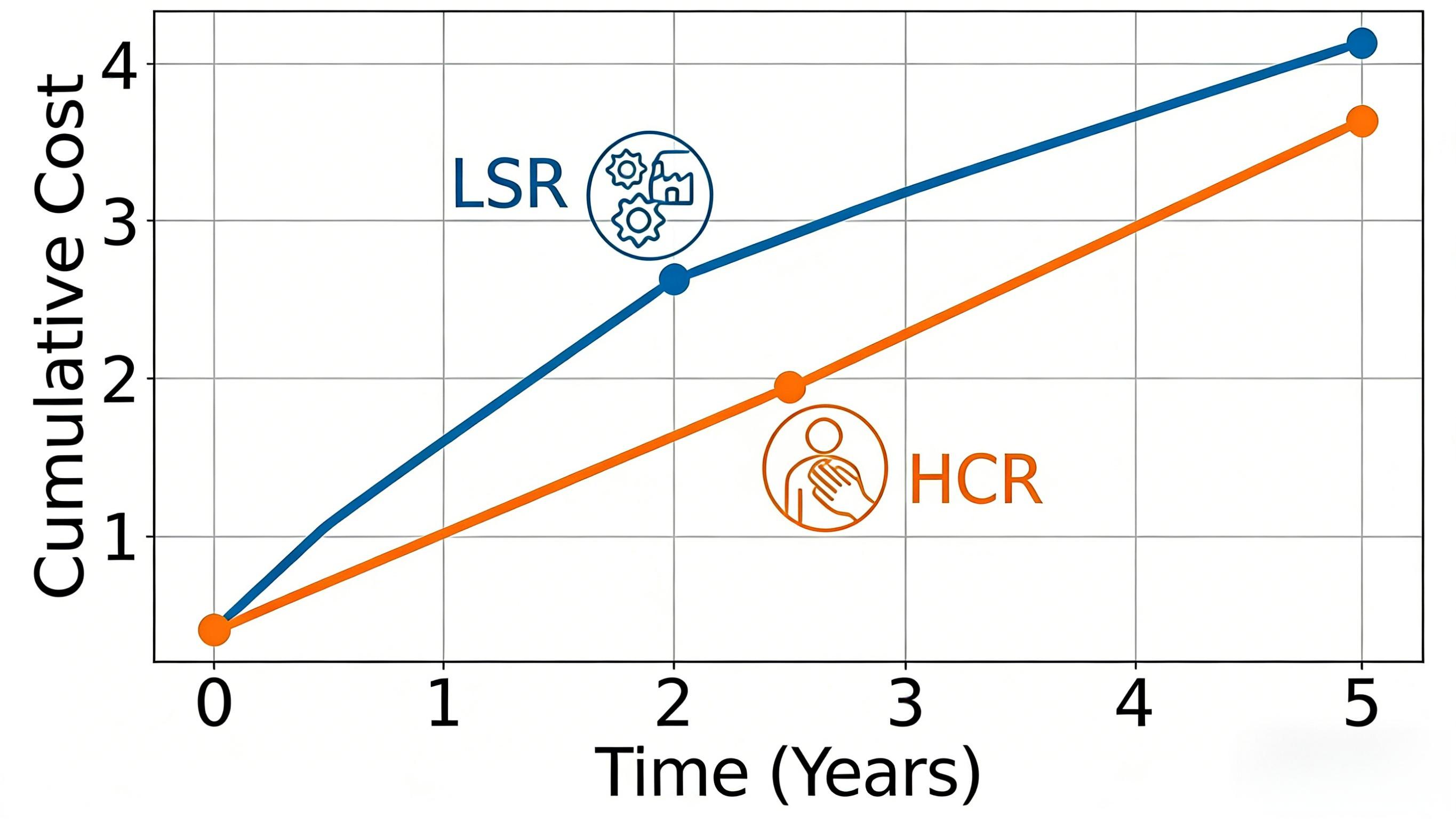

LSR's economic advantages are evident at this scale. Volume fully amortizes tooling investments within 6 to 12 months. Faster cycles, reduced waste, and automated quality, combined with per-unit savings, can create five-year savings that are typically 40% higher than those of HCR.

LSR's 100,000 annual units can save you approximately $125,000 annually through labor savings, reduced material waste and secondary operations. Besides, LSR has a $435,000 advantage in the five-year cost of ownership for typical scenarios.

Matching Silicone Materials to Product Applications

Baby Products

Pacifiers and baby bottle nipples typically require LSR's ultra-soft formulations (15-25 Shore A) and their solid tear resistance (30-40 kN/m, as opposed to 20-30 kN/m for HCR), for safety. For suction plates, LSR's complete cavity filling ensures that LSR can achieve consistent wall thickness across complex geometries.

CPSIA compliance and LFGB certification requirements favor LSR's minimal extractables and automated processing.

Travel Accessories

Only LSR can deliver the 0.5-1.0mm walls and more than 10,000-fold cycles required for collapsible water bottles. TSA-compliant water bottles require precision valves with tolerances of less than 0.1mm. This market segment is experiencing annual growth of 8 to 10 percent. Premium LSR products offer a 30-50% price advantage.

Household Items

Premium food storage bags typically benefit from the LSR’s uniform wall thickness of 0.5 to 8mm and its crystal-clear appearance. Mid-market alternatives utilize HCR for thicker designs (1.5-2mm) that are produced in quantities of less than 50,000 units per year. On the other hand, premium brands of kitchen utensils specify LSR to ensure seamless construction and withstand heat resistance up to 600°F.

Why Our Dual-Process Manufacturing Creates Competitive Advantage

Most silicone manufacturers are only able to offer HCR compression molding or LSR injection molding. This limitation to a single process creates a bias towards the available equipment, regardless of whether it is optimal for your project.

Our Unbiased Material Recommendation Process

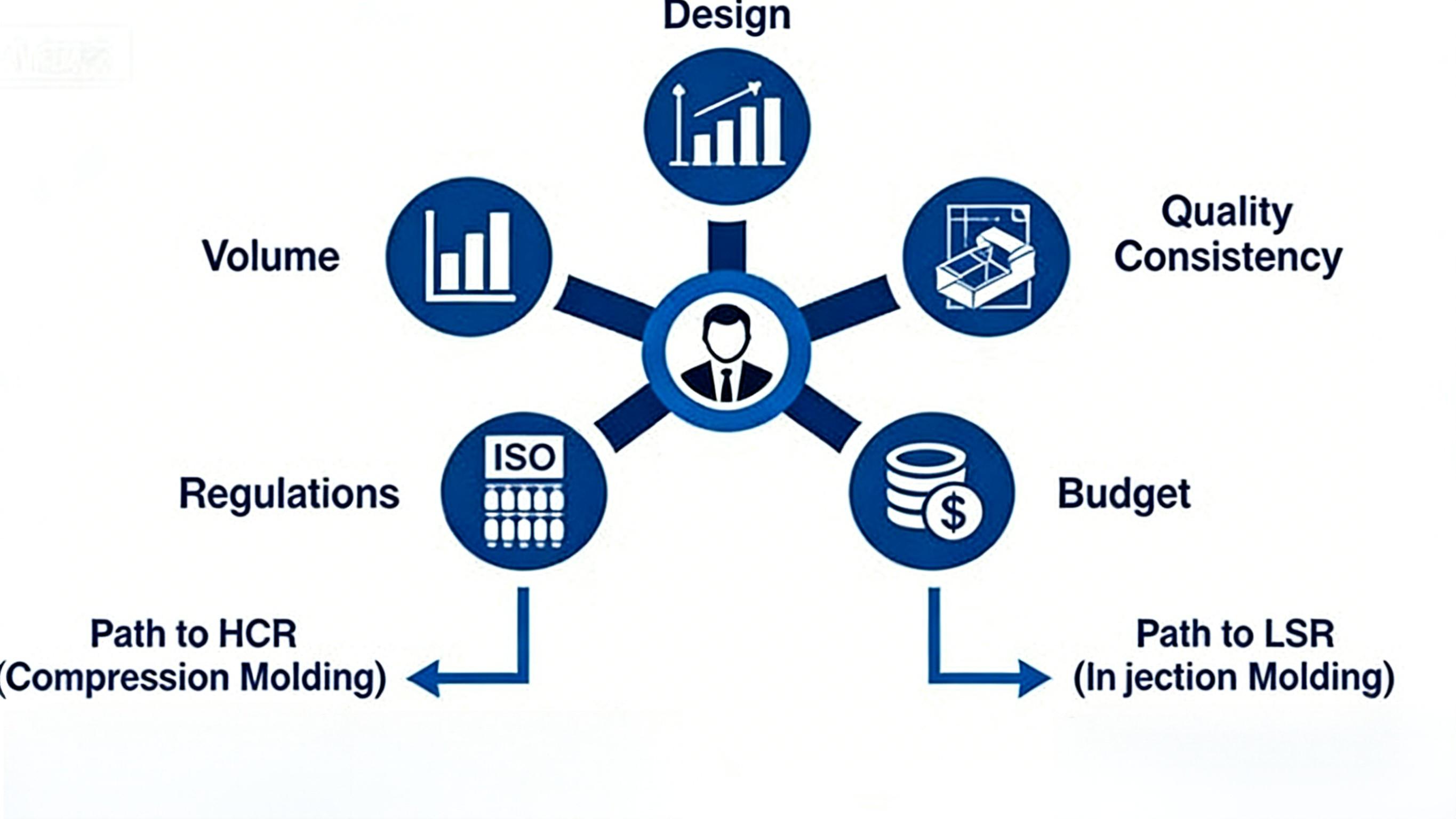

With both HCR compression molding and LSR injection molding capabilities across five production bases, our engineers offer reliable, objective advice. The selection of materials will depend on your requirements for volume, design, consistency in quality, regulatory requirements and budget.

The dual-process expertise allows for flexible scaling strategies. Brand owners can start with HCR prototyping for $35,000 in tooling costs to validate the market and then seamlessly transition to LSR production when volume warrants. A single supplier relationship reduces costs by eliminating retooling, keeps design knowledge and ensures continuity of quality through all growth phases.

Our Manufacturing Credentials

Our experience in silicone manufacturing spans over 18 years, encompassing a range of products including baby products, household items, and travel accessories. More than 300 proprietary patents demonstrate our leadership in innovation. Besides, certifications include ISO 9001, ISO 13485, FDA 21 CFR 177.2600 and CPSIA compliance.

The engineering resources include a 15-person design team with an average of more than 10 years of experience and a chief engineer with over 20 years of silicone expertise. Rapid prototyping produces functional samples within 3 to 5 working days. Order quantities as low as 100 units allow for thorough market testing prior to full production commitment.

Make Your Material Decision

Material selection is based on the unique combination of your design complexity, production volumes, and market positioning. Matching the production process with your product is essential for optimal performance and profitability, whether you are launching a prototype or scaling up to mass production. Our engineering team will provide an unbiased analysis that is tailored to your needs, not our equipment. Contact us today to get cost modeling, compliance maps, and production process prototypes. This will help you accelerate the path from your concept to a successful market launch.